포장 기계: 정밀 곡물 재료 전제 제조 플라스틱 봉지를 위한 완전 자동 가중 포장 기계

| 유형 | 자동 포장기 | 제품명 | 음식 과립 다중 스테이션 포장 기계 |

|---|---|---|---|

| 차원 (L*W*H) | L1900*W1400*H1450 | 무게(KG) | 1300 |

| 전압 | 110V 220V 380V 50Hz/60Hz | 생산능력 | 20bag/min, 50bag/min, 30bag/min |

| 강조하다 | 완전 자동 곡물 봉지 기계,사전 제조된 플라스틱 봉지 포장 기계,얇은 곡물 가량 포장 기계 |

||

| 포장기 유형 | |

|---|---|

| 그랜 팩 머신 | |

| 액체 포장 기계 | |

| 분말 포장기 | |

| 서 있는 봉지 포장 기계 | |

| 수직 포장 기계 | |

| 수평 포장기 | |

| 티백 기계 | |

| 커피 콩 포장 기계 | |

| 수평 포장기 |

포장 기계: 미세 입자 재료용 완전 자동 계량 포장기 - 기성 플라스틱 백

8 스테이션 백설탕 포장기는 백설탕의 자동 계량, 충전 및 밀봉을 위해 특별히 설계된 중고속 포장 장비입니다. 설탕 정제 및 식품 가공 산업에서 널리 사용됩니다.

I. 핵심 개념

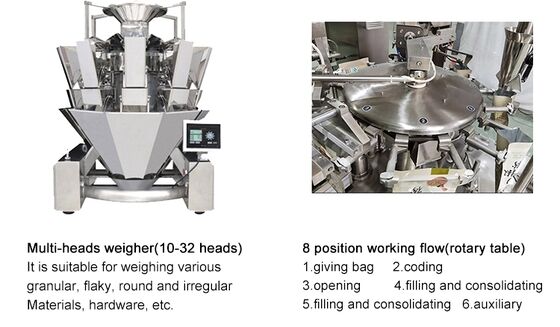

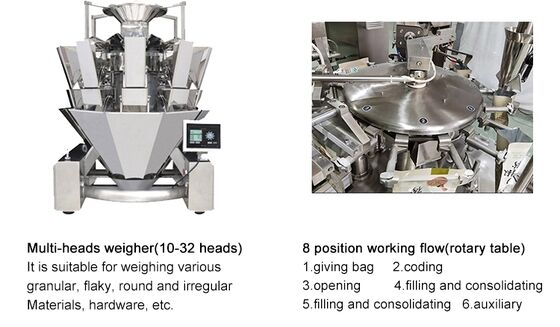

"8개 스테이션"은 기계에 있는 8개의 동일한 계량 또는 포장 워크스테이션을 의미합니다. 이 스테이션은 휠 스포크처럼 메인 샤프트(턴테이블)를 중심으로 회전하며 각자의 작업을 순차적으로 완료합니다. 이러한 설계는 병렬 작동을 통해 포장 속도를 크게 증가시켜 일반적으로 시간당 1200-2000 봉지 이상을 달성합니다.

II. 주요 특징

1. 높은 효율성: 8개의 스테이션이 동시에 작동(예: 1개 공급, 1개 계량, 1개 배출, 1개 밀봉)하므로 속도가 단일 스테이션 또는 이중 스테이션 장비보다 훨씬 빠릅니다.

2. 높은 정밀도: 고정밀 센서와 컴퓨터 제어 멀티 헤드 스케일을 사용하여 공급하므로 계량 정확도가 높으며 일반적으로 ±0.5g 이내로 제어 가능하며 국가 정량 포장 규정을 준수합니다.

3. 높은 자동화 정도: 공급, 계량, 백 제작/개봉, 충전, 밀봉에서 코딩까지 전체 프로세스가 완전히 자동화되어 수작업 의존도를 줄입니다.

4. 광범위한 적용 가능성: 500g, 1kg, 2kg, 5kg의 소형 또는 중형 백과 같은 다양한 크기의 과립 설탕을 포장할 수 있습니다.

5. 우수한 안정성: 성숙한 기계 구조, 강력한 연속 작동 능력, 대량 생산에 적합합니다.

III. 일반적인 워크플로우(기성 백 수직 포장을 예로 들면)

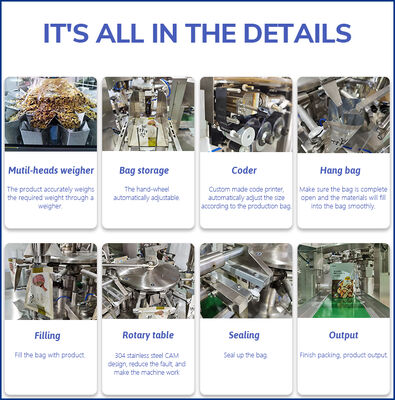

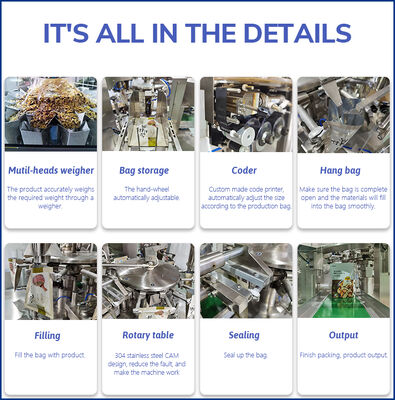

1. 공급: 과립 설탕은 엘리베이터를 통해 컴퓨터 제어 멀티 헤드 스케일의 버퍼 호퍼 및 계량 호퍼로 들어갑니다.

2. 정밀 계량: 멀티 헤드 스케일의 멀티 헤드 스케일 시스템은 최적의 조합을 빠르게 계산하여 정확한 무게의 설탕을 가이드 슈트를 통해 포장기의 8개 회전 스테이션의 계량 실린더로 공급합니다.

3. 백 회수 및 개봉: 로봇 팔이 백 매거진에서 기성 플라스틱 백을 회수하여 백 입구를 엽니다. 각 스테이션은 하나의 백에 해당합니다.

4. 충전: 턴테이블이 회전합니다. 설탕이 들어 있는 계량 실린더가 충전 위치에 도달하면 밸브가 열리고 설탕이 아래 백으로 떨어집니다.

5. 밀봉: 턴테이블이 계속 회전하여 열 밀봉 또는 솔기 밀봉 위치로 이동하여 밀봉합니다.

6. 출력: 밀봉된 백은 컨베이어 벨트로 배출되어 계산, 코딩(예: 생산 날짜, 배치 번호) 또는 상자 포장을 수행합니다.

IV. 핵심 시스템 구성 요소

1. 리프팅 및 공급 시스템: 설탕을 계량 호퍼로 공급합니다.

2. 고정밀 컴퓨터 결합 스케일: 이는 정확성과 속도에 매우 중요합니다. 일반적으로 8, 10 또는 14개의 스케일이 있으며 8 스테이션 메인 유닛과 페어링됩니다.

3. 8 스테이션 로터리 메인 유닛: 백 고정, 충전 및 기타 작업을 담당하는 핵심 액추에이터입니다.

4. 백 제작 또는 백 픽업 시스템: 롤 필름 또는 기성 백 사용 여부에 따라 구성됩니다.

5. 열 밀봉/재봉 시스템: 플라스틱 백을 밀봉합니다.

6. 제어 시스템: PLC(Programmable Logic Controller) + 터치 스크린 HMI(Human-Machine Interface)는 전체 기계의 조정된 작동을 제어하고 매개변수 설정, 상태 모니터링 및 출력을 계산할 수 있습니다.

7. 컨베잉 및 코딩 시스템: 완제품을 컨베잉하고 코딩을 수행합니다.

기계 사양:

| 항목 | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| 포장속도 | 최대 60 봉지/분, 포장 필름의 품질, 포장 재료, 포장 중량 등에 따라 다름 | ||

| 백 크기 | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| 백 유형 | 기성 백, 스탠드업 백, 사면 밀봉 백, 삼면 밀봉 백, 특수 모양 백 | ||

| 계량 범위 | 10g-1kg | 10g-2kg | 10g-3kg |

|

측정 정확도 |

*≤±0.5~1%, 측정 장비 및 재료에 따라 다름. | ||

| 최대 백 너비 | 200mm | 250mm |

300mm |

| 가스 소비량 | 0.8Mpa 0.3m3/min (사용자 공급) | ||

| 총 전력/전압 | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| 에어 컴프레서 | 1CBM 이상 | ||

| 치수 | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| 기계 중량 | 1300kg | 1400kg | 1500kg |

| 작업 흐름 | 백 공급→코딩→백 개봉(또는 지퍼 백 개봉)→충전→ 보조→배기→열 밀봉→제품 형성 및 출력. | ||

| 적용 범위 | 과립 유형: 결정성 글루탐산나트륨, 과립 약물, 캡슐, 씨앗, 화학 물질, 설탕, 치킨 에센스, 해바라기 씨, 견과류, 살충제, 비료 등 | ||

(귀하의 필요에 따라 독점적인 맞춤형 서비스를 제공할 수 있습니다!)

![]()

![]()

![]()

![]()