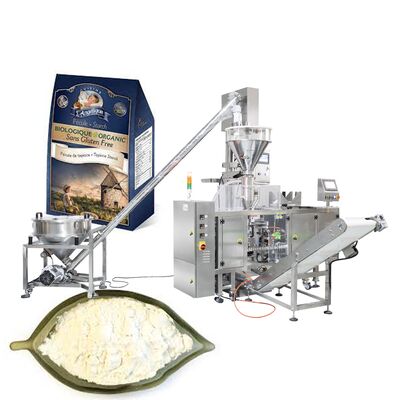

식품 및 상품 등급 플라스틱 파우치용 모터 구동 시스템을 갖춘 자동 분말 충전, 밀봉 및 라벨링 기계

| 유형 | 다중기능 패키징 머신 | 제품명 | 미니 도이팩 포장기 |

|---|---|---|---|

| 체중(kg) | 1300 | 애플리케이션 | 음식, 음료, 상품 |

| 포장재 | 플라스틱 | 자동 등급 | 오토매틱 |

| 강조하다 | 파우치용 자동 분말 충전기,모터 구동 시스템을 갖춘 Doypack 포장기,식품 등급 파우치 밀봉 및 라벨링 기계 |

||

| 포장기 유형 | |

|---|---|

| 그랜 팩 머신 | |

| 액체 포장 기계 | |

| 파우더 포장 기계 | |

| 서 있는 봉지 포장 기계 | |

| 수직 포장 기계 | |

| 수평 포장기 | |

| 티백 기계 | |

| 커피 콩 포장 기계 | |

| 수평 포장기 |

자동 파우더 채우기, 밀봉 및 라벨링 기계

I. 단역 파우더 포장 기계 는 무엇 인가?

이것은 자동 또는 반자동 포장 기계입니다. 분말 물질을 양적으로 채우고 밀폐하는 데 초점을 맞추고 있습니다. (유 분말, 단백질 분말, 향신료, 첨가물,그리고 의약품 분말) 를 미리 만든 포장 봉지에"일종 역"은 하나의 작업 주기에 주요 프로세스 (백 픽업, 가방 열기, 채우기, 밀폐 및 가방 배하) 가 순차적으로 완료된다는 것을 의미합니다.여러 스테이션 회전 기계에서와 같이 동시에 여러 프로세스를 수행하는 대신.

일반적으로 수동 포장과 완전 자동화 된 고속 생산 라인 사이에 있습니다.자동화 업그레이드를 추구하는 중소기업의 이상적인 입문점과 선택지.

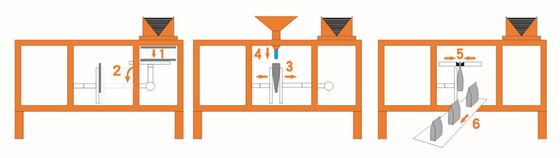

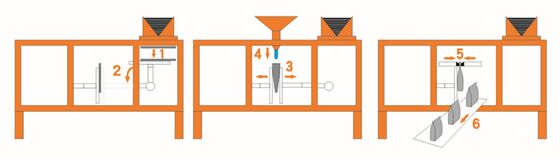

II. 주요 업무 원칙 및 프로세스

단일 스테이션 자동 파우더 포장 기계의 전형적인 작업 흐름은 다음과 같습니다.

1가방 수리 및 열기: 로봇 팔 또는 흡입컵은 미리 만든 빈 가방 (일직 봉지, 뒷 봉지, 세 면 봉지 가방 등) 을 수리합니다.) 가방을 매거진에서 꺼내서 흡입컵이나 클램프를 사용하여 가방을 정확하게 열습니다., 채울 준비가 되어 있습니다.

2양적 충전: 이것은 핵심 단계입니다. 파우더는 나사, 측정 컵 또는 조합 척도로 양적으로 충전됩니다.

스크루 채우기: 가장 일반적인 방법, 양적 채우는 정밀 스크루의 회전 수를 제어함으로써 달성됩니다.좋은 유동성 또는 일반적인 특성을 가진 대부분의 파우더에 적합합니다.

순중량 척도 채우기: 무게 센서를 사용하여 목표 무게에 도달하면 채우기를 중단합니다. 이 방법은 가장 높은 정확도를 제공하며 고부가가치 재료에 적합합니다.

총중량 척도 채우기: 포장과 함께 가방을 무게합니다.

3보조 기능:

진동/타핑: 충전 중 또는 후에는 가루를 압축하고, 가루 안의 공기를 줄이고, 충전 정확성과 포장 미용을 향상시키기 위해 가루가 부드럽게 진동됩니다.

가방 열기 청소: 고압 가스를 사용하여 가방 열기에서 흡수 된 분자를 날려 깨끗하고 안전한 밀폐를 보장합니다.

4봉쇄 및 봉지 방출: 열 봉쇄 장치가 봉지를 열고 압축하여 봉쇄합니다. 봉쇄 후 로봇 팔은 완성 된 봉지를 컨베이어 벨트 또는 수집 통에 놓습니다.

주요 구성 요소

1프레임 및 제어 시스템: 전체 기계를 지원합니다.핵심 부품은 PLC (프로그램 가능한 논리 제어기) 와 매개 변수 (중량 및 속도 등) 를 설정하고 동작을 모니터링 할 수 있는 터치 스크린 인간 기계 인터페이스입니다..

2.바그 공급 시스템: 미리 만든 바그를 깔끔하게 쌓는 바그 저장 장치.

3.백 검색 및 오픈 메커니즘: 세르보 모터로 작동하는 로봇 팔과 진공 흡수 컵 집합체.

4물자 공급 시스템: 저장 용기, 믹서기 (아보를 방지하기 위해) 및 공급 나사 포함됩니다.

5무게 시스템: 정밀 나사 집합 및 무게 센서 (또는 부피 측정 컵).

6밀폐 시스템: 온도 및 시간 조절 가능한 열 밀폐 스트립.

7배포 컨베이어 벨트: 완성 된 가방을 배달합니다.

IV. 전형적인 응용 분야 (포우더)

1식품산업: 우유가루, 소아 우유가루, 커피가루, 향신료가루 (닭고기 에센스, 후추가루), 밀가루, 식품 첨가물, 인스턴트 음료가루.

2건강 제품 및 의약품: 단백질 분말, 영양 분말, 전통 중국 의약품 분말, 고체 음료.

3화학 산업: 세탁용 세탁제, 염료, 색소, 화학 원료, 첨가물.

4농업 산업: 살충제 가루, 비료, 사료 첨가물.

기계 사양:

| 항목 | 200 | 300 | 430 |

| 가방 재료 | 다층 복합 전공 봉지 (예: PET/PE) | ||

| 가방 크기 | 100mm≤L≤200mm | 100mm≤L≤300mm | 100mm≤L≤430mm |

| 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm | |

| 가방 종류 | 3쪽 봉인 가방, 서 있는 가방 | ||

| 업그레이드 가능한 가방 유형 | 제1호 |

가세트 가방, 지퍼 가방, 평면 바닥 가방 (기능적 장치의 추가 구매가 필요합니다.) |

|

| 속도 | 0~26백/분 | 0~15백/분 | |

| 밀폐형 | 직물 | 직선 곡물, 피치 1mm (선택성 reticulate) | |

| 밀봉 너비 | 8mm | 10mm ((5--20mm는 사용자 정의 될 수 있습니다) | |

| 전압 | 220V, 단일 단계, 50/60HZ, 1KW | 220V, 단일 단계, 50/60HZ, 1.2KW | |

| 공기 압력 | 0.65Mpa | ||

| 공기 소비 | 0.2m3/min | 0.3m3/min | |

| 표준 기계, 추가 기능이 없습니다 | |||

| 몸의 크기 | 1080*535*1010mm | 1770*600*1230mm | 1770*600*1360mm |

| 포장 크기 | 1240*670*1320mm | 1860*710*1550mm | 1860*710*1650mm |

| 비연화 목재 케이스 수출 | |||

(우리는 당신의 필요에 따라 독점적인 포장 기계 사용자 정의 서비스를 제공 할 수 있습니다! 물론, 당신이 필요로하는 경우, 우리는 또한 사용자 정의 가방 서비스를 제공 할 수 있습니다)

![]()

![]()