Eight-Station Rotary Table Automatic Bagging and Packaging Machine

무료샘플과 쿠폰을 위해 나와 연락하세요.

WhatsApp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 유형 | 자동 포장 기계 | 제품 이름 | 음식 과립 다중 스테이션 포장 기계 |

|---|---|---|---|

| 치수 (l*w*h) | L1900*W1400*H1450 | 체중 (kg) | 1300 |

| 전압 | 110V 220V 380V 50Hz/60Hz | 생산 능력 | 20bag/min, 50bag/min, 30bag/min |

| 강조하다 | rotary table bagging machine,automatic granule packaging machine,eight-station packaging machine with warranty |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

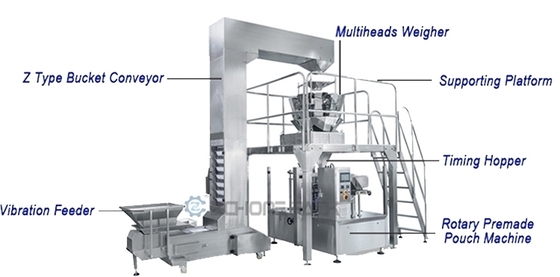

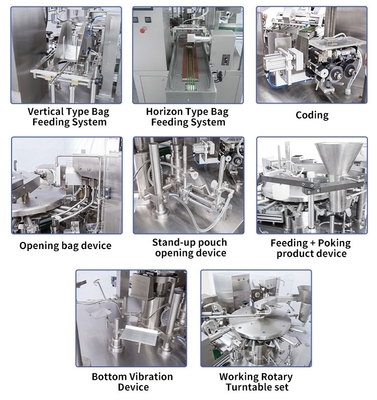

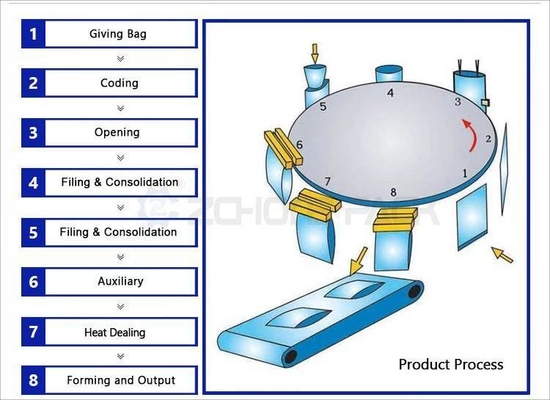

Eight-Station Rotary Table Automatic Bagging and Packaging Machine (with Automatic Desiccant Delivery System)

This eight-station rotary table automatic bagging and packaging machine is specifically designed for the final packaging of "Yuanqi Exploding Beads" products. Its core function is to automatically combine the boxed product (small boxes of Yuanqi Exploding Beads) with desiccant, then pack it into pre-made bags and seal them.

1. Equipment Function Overview

This machine utilizes an eight-station rotary table to accurately and efficiently pack boxed "Yuanqi Exploding Beads" and a small desiccant packet into pre-made bags. It then performs heat sealing, output, and counting operations. It automates the entire process, from bulk packaging to final retail packaging, significantly improving production efficiency and hygiene standards.

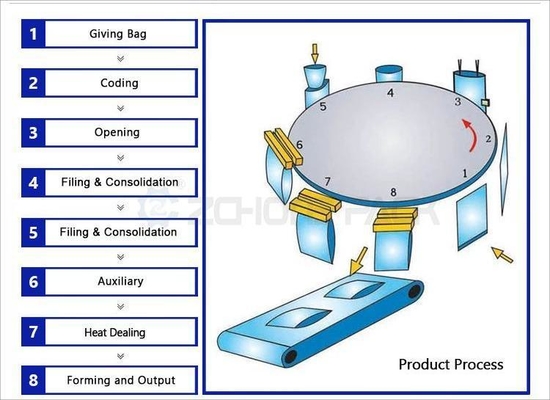

2. Detailed Workflow of Each Station

A complete packaging cycle is typically completed sequentially at eight stations, each performing a specific action, producing a bag of finished product after one rotation.

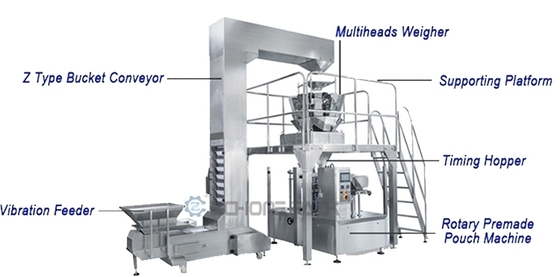

3. Core Features and Advantages of the Equipment

High Efficiency: Eight stations operate simultaneously in a cycle, reaching speeds of dozens of packages per minute.

High Precision: Utilizing servo motors and PLC control, each movement is precise and accurate, ensuring high-quality feeding and sealing.

High Hygiene: Food-contact parts of the equipment can be constructed of stainless steel for easy cleaning and compliance with GMP standards.

Flexibility: By replacing molds and adjusting the program, it can accommodate pre-made bags, product boxes, and desiccants of varying sizes.

User-Friendly Operation: Equipped with a human-machine interface (HMI) touch screen, it facilitates parameter setting and monitors operating status and production data.

High Stability: The sophisticated mechanical structure and reliable electronic control system ensure long-term stable operation.

4. Summary

The eight-station packaging machine you described is a key device connecting front-end cartoning and back-end case packing. It perfectly solves the problem of automatically combining small box products and auxiliary packages (desiccant) into bags, realizing the automated and intelligent upgrade from "box" to "bag". It is an ideal choice for improving efficiency and quality control in modern food and health product production lines.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm |

300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()