백두대간알을 위한 8개의 스테이션 가방식 포장 기계

무료샘플과 쿠폰을 위해 나와 연락하세요.

WhatsApp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 유형 | 자동 포장 기계 | 제품 이름 | 음식 과립 다중 스테이션 포장 기계 |

|---|---|---|---|

| 치수 (l*w*h) | L1900*W1400*H1450 | 체중 (kg) | 1300 |

| 전압 | 110V 220V 380V 50Hz/60Hz | 생산 능력 | 20bag/min, 50bag/min, 30bag/min |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

백두대간알을 위한 8개의 스테이션 가방식 포장 기계

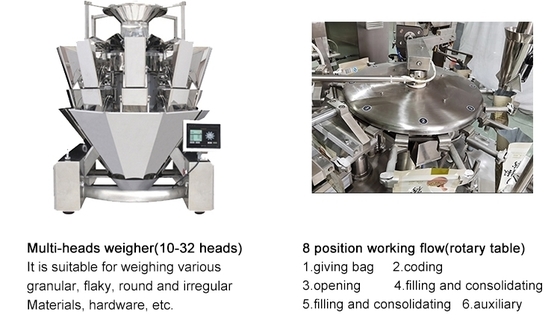

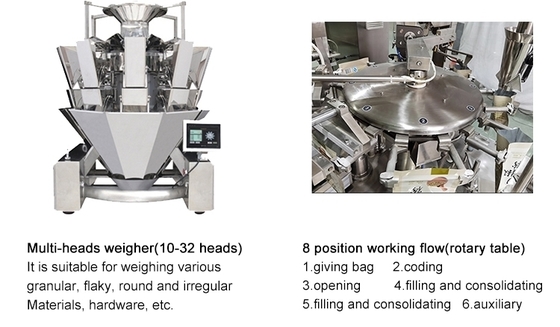

백두콩용 8단지 봉지식 포장기 는 백두콩을 포장하기 위해 특별히 설계된 봉지식 자동 포장기입니다.그것은 완전히 자동화 된 생산 라인 운영을위한 8 개의 작업 스테이션 (스테이션) 을 갖추고 있습니다..

1핵심 개념 분석

흰 렌즈: 포장되는 제품입니다. 이것은 다음과 같은 특징을 가진 곡물 농산물입니다.

외형: 곡물형, 크기가 비교적 균일하며 유동성이 좋다.

요구 사항: 포장 과정에서는 분쇄와 정확한 측정이 피할 수 있습니다.

가방식 포장 기계: 포장 기계의 일종.

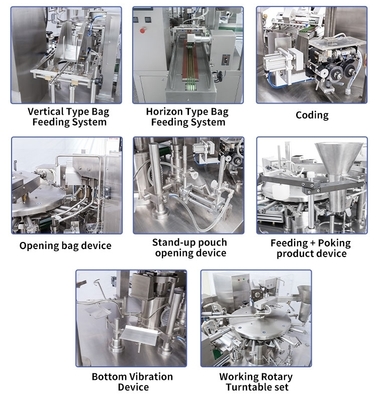

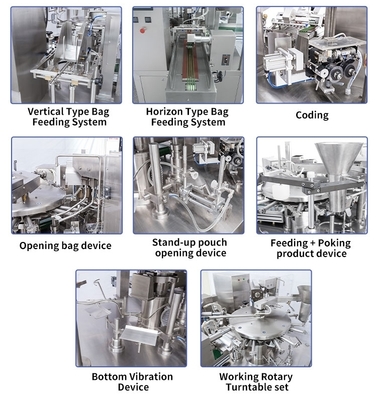

2작동 원칙:일반적인 "백식 포장 기계"와 달리 (필름 롤, 채우기, 봉인 등으로 시작) 팩식 포장 기계는 미리 만든 봉지를 사용합니다. 기계는 자동으로 전체 프로세스를 완료합니다.가방 제거를 포함하여, 가방 열기, 측정 및 채우기, 환기 (선택), 밀폐 및 배charge.

장점:

다양한 패키지 스타일: 다양한 아름다운 사전 제작 된 서있는 봉지, 자부지 가방, 지퍼 가방 및 토트백을 사용할 수 있으며 제품의 품질을 향상시킵니다.

높은 효율성: 제한된 패키지 변동과 안정적인 속도와 함께 제품에 특히 적합합니다.

좋은 재료 적응성: 채우는 부드럽고 흰 렌즈와 같은 곡성 물질에 대한 막힘을 방지합니다.

8단계: 기계의 자동화 수준과 기능적 복잡성

스테이션은 포장 기계의 회전 테이블에 있는 각 작업 스테이션을 가리키며, 각각의 작업 스테이션은 특정 포장 단계에 책임이 있다.8개의 스테이션은 기계가 동시에 8개의 다른 작업을 수행할 수 있다는 것을 의미합니다., 극도로 높은 효율을 가져옵니다.

3. 작업 흐름 (일반적인 8개 역 시스템에는 다음 단계가 포함될 수 있다):

스테이션 1 (백 로딩): 로봇 또는 흡입컵이 사전 제조 된 봉지를 바그 매거진에서 정확하게 제거합니다.

역 2 (백 열기): 손잡이가 가방 열기를 잡으며, 공기 붓기 또는 흡입컵이 채워질 준비를 위해 가방 열기를 열는다.

스테이션 3 (계량 채우기): 이것은 핵심 스테이션입니다. 중력 측정 하프 (다중 머리 조합 가중기) 또는 부피 측정 컵을 사용하여,적당한 양의 흰 렌즈가 열린 봉지에 쏟아집니다.이것은 각 가방의 정확한 무게를 보장하는 데 매우 중요합니다.

스테이션 4 (비브레이터리 블랭킹 / 보조 블랭킹): 부드러운 진동 또는 막대기 삽입 장치로 가방 열기와 내부 벽에 잔류 물질이 없도록 보장하여 깨끗한 밀폐를 보장합니다.

스테이션 5 (호흡기): 환기를 필요로 하는 제품에서 이 스테이션은 공기를 배출하기 위해 가방을 압축하여 포장지를 더 단단하고 미용적으로 더 매력적으로 만듭니다.그리고 보관 기간을 연장합니다 (하얀 렌즈에 필요한 것 처럼).

스테이션 6 (밀폐): 핵심 스테이션. 열 밀폐기는 봉지를 완료하기 위해 봉지 열과 압력을 가집니다. 이것은 직선 밀폐, 뒷 밀폐 또는 지그자그 밀폐가 될 수 있습니다.

스테이션 7 (냉각 및 형성): 열 밀폐는 안정적이고 미적 인 밀폐를 보장하기 위해 냉각되고 모양이됩니다.

역 8 (부하 및 출하): 포장 된 완성 된 가방을 다음 단계 (박스, 코딩 및 금속 검사) 를 위해 컨베이어 벨트에 놓습니다.

참고: 작업 스테이션의 특정 순서와 기능은 제조업체의 설계 및 고객의 필요에 따라 사용자 정의 될 수 있습니다. 예를 들어 검사 스테이션 (예를 들어, 무게 재검토,금속 탐지) 또는 라벨링 스테이션이 추가 될 수 있습니다..

4장비 작업 흐름 요약

Empty bag → Automatic bag loading → Bag opening → Accurately measure and fill with white lentils → Bag opening trimming → Air removal → Heat-press sealing → Cooling and setting → Finished product output

기계 사양:

| 항목 | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| 포장속도 | 포장 필름의 품질, 포장 재료, 포장 무게 등에 따라 최대 60 봉지/분 | ||

| 가방 크기 | (L) 100-300mm (W) 70-200mm | (L) 100-350mm (W) 130-250mm | (L) 150-450mm (W) 200-300mm |

| 가방 종류 | 사전 제작된 가방, 서있는 가방, 4면 봉인 가방, 3면 봉인 가방, 특수 모양의 가방 | ||

| 무게 범위 | 10g-1kg | 10g-2kg | 10g~3kg |

|

측정 정확성 |

* 측정 장비와 재료에 따라 ±0.5~1%입니다. | ||

| 최대 봉지 너비 | 200mm | 250mm |

300mm |

| 가스 소비 | 00.8Mpa 0.3m3/min (사용자 공급) | ||

| 전체 파우더/전압 | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| 공기 압축기 | 1CBM 이하 | ||

| 차원 | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| 기계 무게 | 1300kg | 1400kg | 1500kg |

| 작업 흐름 | 주입 가방→코딩→오프닝 가방 ((또는 오픈 지퍼 가방) → 채우기→ 보조→ 배기가스→열 밀폐→형조 및 출력 제품. | ||

| 적용 범위 | 알갱이형: 결정성 단나트륨 글루타마트, 알갱이형 약물, 캡슐, 씨앗, 화학물질, 설탕, 닭고기 에센스, 멜론 씨앗, 견과류, 농약, 비료 등 | ||

(우리는 당신의 필요에 따라 독점적인 맞춤 서비스를 제공 할 수 있습니다!)

![]()

![]()

![]()

![]()