자동 칠리 파우더 포장기 60 봉지/분

무료샘플과 쿠폰을 위해 나와 연락하세요.

WhatsApp:0086 18588475571

위챗: 0086 18588475571

스카이프: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 종류 | 자동 파우더 패키징 머신 | 아프테르와르라티 Service1 | 비디오 기술 지원 |

|---|---|---|---|

| 아프테르와르라티 Service2 | 온라인 지원 | 아프테르와르라티 Service3 | 부품 |

| 아프테르와르라티 Service4 | 현장 유지 보수와 수리 서비스 | 로컬서비스 Location5 | 아무 것도 |

| 강조하다 | 자동 칠리 파우더 포장기,고속 분말 포장기,분당 60 봉지 포장기 |

||

| 포장기 유형 | |

|---|---|

| 그랜 팩 머신 | |

| 액체 포장 기계 | |

| 파우더 포장 기계 | |

| 서 있는 봉지 포장 기계 | |

| 수직 포장 기계 | |

| 수평 포장기 | |

| 티백 기계 | |

| 커피 콩 포장 기계 | |

| 수평 포장기 |

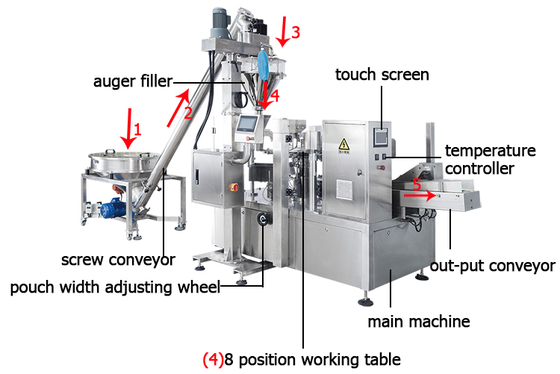

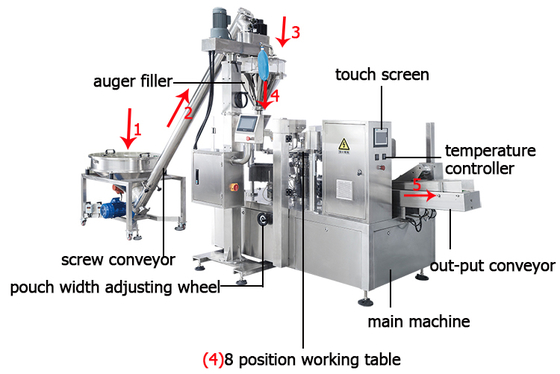

칠리 파우더 향신료 파우더 봉지 공급 자동 포장 기계

The eight-station bag-feeding chili powder packaging machine is an efficient and fully automatic packaging equipment designed for powdered materials such as chili powder and suitable for medium and large-scale production.

1장비 개요

작동 원리: 회전 8 스테이션 회전 테이블을 통해, 가방을 취하고, 가방을 열고, 측정 및 채우기, 배기가스, 밀폐, 코딩, 테스트,그리고 완성된 제품 생산은 순서대로 완료됩니다..

주요 장점:

높은 효율성: 8개의 스테이션이 동시 작동하며, 속도는 40-60백/분까지 도달할 수 있습니다.

높은 정확성: 세르보 모터 제어 + 나사 측정, 오류 ≤±1%

넓은 적응력: 다양한 종류의 가방 (뒤로 밀폐 된 가방, 자부지 가방, 네 면 밀폐 된 가방과 같은) 을 처리 할 수 있습니다.

2칠리 파우더를 위한 특별 디자인

먼지 방지 시스템:

완전히 닫힌 실로 + 마이너스 압력 먼지 흡수 장치

실리콘 먼지 커튼이 나사 공급 포트에 설치됩니다.

고착 방지 처리:

칠리 파우더와 접촉하는 부품 (미터 스크루와 같이) 은 거울 스테인레스 스틸 또는 테플론 코팅으로 만들어집니다.

반 정적 조치:

토착 설계 + 이온 바람 막대 (포더가 포장 필름에 붙는 것을 줄이십시오.)

3선택 고려 사항

물질 속성 적응:

칠리 파우더에 기름이나 덩어리가 들어있다면 진동 아크 분쇄 장치를 추가해야 합니다.

포장 재료:

반 정적 복합 필름 (PET/AL/PE 등) 또는 알루미늄 포일 봉지를 사용하는 것이 좋습니다.

확장 기능:

선택적 질소 충전 및 보존 모듈 (백의 산소를 대체합니다.)

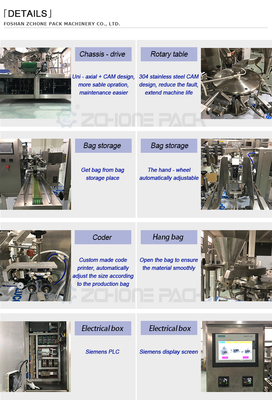

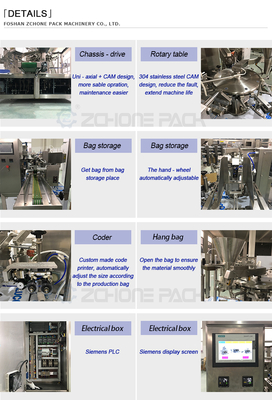

4유지보수 및 문제 해결

매일 유지보수:

매 셔프트마다 측정 스퀴와 흡입컵을 청소합니다.

열 봉쇄 스트립의 마모를 매주 확인합니다.

일반적인 결함:

가방 열기 장애: 진공 정도 또는 압축 공기 압력을 확인합니다.

약한 밀폐: 온도/압을 조정하거나 포장 재료를 교체합니다.

5응용 시나리오

적용 가능한 제품: 칠리 파우더, 후추 파우더, 5개 향신료 파우더 및 기타 조미료, 또한 우유 파우더 및 단백질 파우더와 같은 파우더로 확장 할 수 있습니다.

기계 사양:

| 항목 | ZC-8200 | ZC-8250 | ZC-8300 |

| 포장 속도 | 최대 60개의 가방/분 | ||

| 가방 크기 | L100~300mm | L100~350mm | L150-450mm |

| W70-200mm | W130-250mm | W200-300mm | |

| 가방 종류 | 미리 만든 가방, 서 있는 가방, 세면 또는 네면 밀폐된 가방, 특수 모양의 가방 | ||

| 무게 범위 | 10g~1kg | 10~2kg | 10g~3kg |

| 측정 정확성 | ≤±0.5 ~ 1.0%, 측정 장비와 재료에 따라 달라집니다. | ||

| 최대 배지 너비 | 200mm | 250mm | 300mm |

| 가스 소비 | 00.8Mpa 0.3m3/min | ||

| 전체 전력/전압 | 1.5kw 380v 50/60hz | 1.8kw 380v 50/60hz | 2kw 380v 50/60hz |

| 공기 압축기 | 최소 1 CBM | ||

| 차원 | L1900*W1400*H1450mm | L2000*W1500*H1550 | |

| 기계 무게 | 1300kg | 1500kg | |

(우리는 당신의 필요에 따라 독점적인 맞춤 서비스를 제공 할 수 있습니다!)

![]()

![]()