혼합 젤 포장 기계

| 제품명 | 주둥이 포장기 | 원래 장소 | 포산 중국 |

|---|---|---|---|

| 애플리케이션 | 음료, 액체 및 주스 | 포장재 | 플라스틱 |

| 전압 | 220V 380V 50/60HZ | 주요 판매 포인트 | 오토매틱 |

| 강조하다 | 혼합 젤 포장 기계,플라스틱 혼합 젤 포장 기계,젤 페이스트 장비 220V |

||

| 포장기 유형 | |

|---|---|

| 그랜 팩 머신 | |

| 액체 포장 기계 | |

| 분말 포장기 | |

| 서 있는 봉지 포장 기계 | |

| 수직 포장 기계 | |

| 수평 포장기 | |

| 티백 기계 | |

| 커피 콩 포장 기계 | |

| 수평 포장기 |

이중 액체 재료 혼합 젤 포장 기계 화학 반응 젤 페이스트 장비 파우치

혼합 액체 젤 패치 포장 기계는 액체, 젤 또는 반유동 물질을 포장하는 데 특별히 사용되는 자동화된 장비입니다. 의약품(해열 패치, 반창고 등), 화장품(마스크팩, 아이패치 등), 건강식품 등 다양한 분야에서 널리 사용됩니다.

1. 장비의 주요 기능

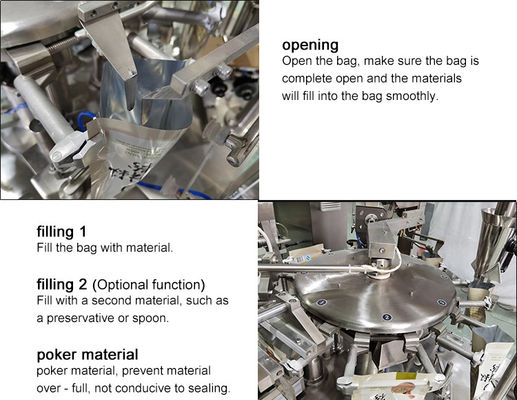

정밀 충전: 높은 정확도(일반적으로 ±1% 오차 이내)로 액체 또는 젤을 정량적으로 채울 수 있습니다.

밀봉 성형: 패치는 누출을 방지하기 위해 열압착, 초음파 또는 냉간 밀봉 기술로 밀봉됩니다.

절단 및 포장: 필요한 모양(원형, 사각형 등)으로 자동 절단하고 단일 조각 포장을 완료합니다.

추가 기능: 일부 장비는 라벨링, 코딩 및 박싱과 같은 후속 프로세스를 지원합니다.

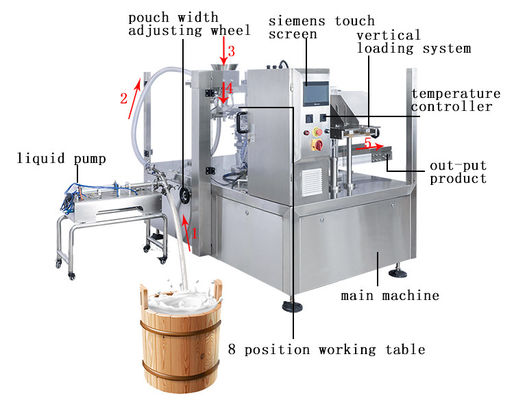

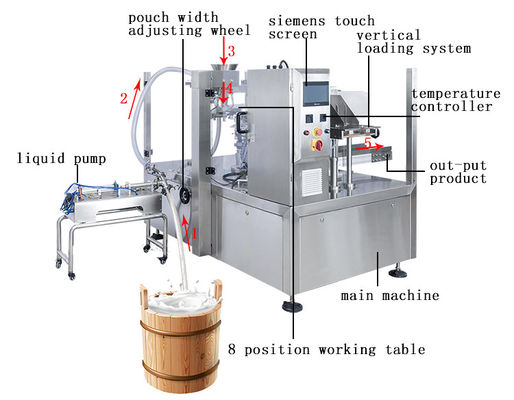

2. 핵심 구조 구성

공급 시스템: 액체/젤 원료를 저장하고 운반하며 침전을 방지하기 위해 교반기가 장착될 수 있습니다.

충전 헤드: 고정밀 펌프(예: 연동 펌프, 기어 펌프)가 충전량을 제어합니다.

3. 성형 부분:

기판 풀림: 뒷면 층(부직포, 필름 등)을 해제합니다.

젤 코팅: 액체를 기판에 균일하게 코팅합니다.

필름 밀봉: 보호 필름을 덮고 열압착 밀봉합니다.

절단 모듈: 깔끔한 가장자리를 보장하기 위해 금형 또는 레이저 절단.

제어 시스템: PLC 또는 터치 스크린 작동, 조절 가능한 매개변수(온도, 속도, 충전량 등).

4. 기술적 특징

위생적인 디자인: 접촉 부분은 GMP 표준을 충족하는 316 스테인리스 스틸 또는 식품 등급 재료로 만들어졌습니다.

광범위한 적응성: 다양한 점도의 액체(예: 수성 젤, 실리콘)를 처리할 수 있습니다.

산화 방지 설계: 일부 장비에는 젤 열화를 방지하기 위해 질소 보호 기능이 장착되어 있습니다.

5. 구매 시 주의사항

재료 특성: 점도, 부식성, 입자 포함 여부 등

용량 요구 사항: 생산에 따라 반자동 또는 완전 자동 모델을 선택합니다.

규정 준수: 업계 표준을 준수해야 합니다(예: 의약품은 FDA 및 CE 인증을 충족해야 함).

확장성: 후속 기능 업그레이드(예: 시각 검사)를 지원할지 여부.

기계 사양:

| 항목 | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| 포장속도 | 최대 60개/분, 포장 필름의 품질, 포장 재료, 포장 중량 등에 따라 다름. | ||

| 가방 크기 | (L)100-300mm (W)70-200mm | (L)100-350mm (W)130-250mm | (L)150-450mm (W)200-300mm |

| 가방 유형 | 사전 제작 가방, 스탠드업 가방, 4면 밀봉 가방, 3면 밀봉 가방, 특수 모양 가방 | ||

| 계량 범위 | 10g-1kg | 10g-2kg | 10g-3kg |

|

측정 정확도 |

*≤±0.5~1%, 측정 장비 및 재료에 따라 다름. | ||

| 최대 가방 너비 | 200mm | 250mm | 300mm |

| 가스 소비량 | 0.8Mpa 0.3m3/min (사용자 제공) | ||

| 총 전력/전압 | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| 에어 컴프레서 | 1CBM 이상 | ||

| 치수 | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| 기계 무게 | 1300kg | 1400kg | 1500kg |

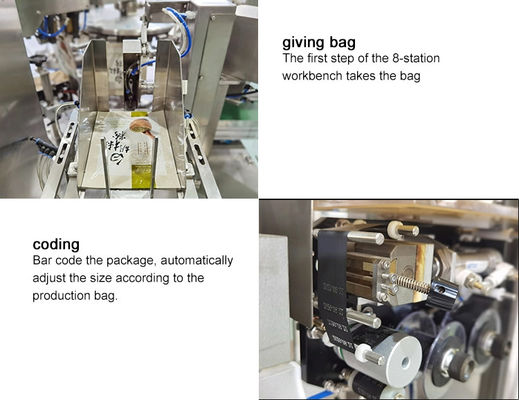

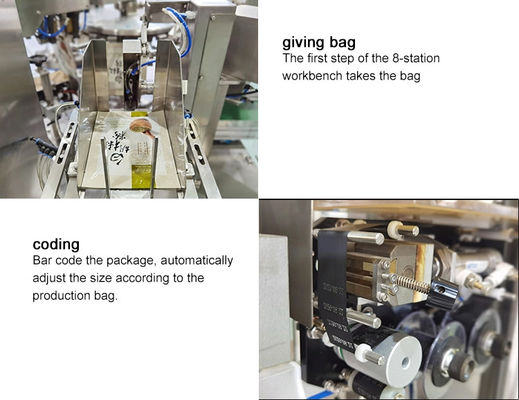

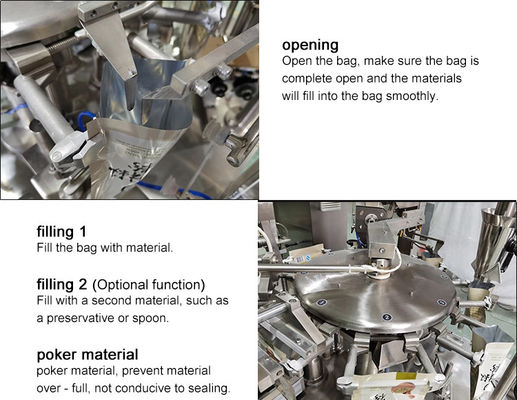

| 작업 흐름 | 가방 넣기→코딩→가방 열기(또는 지퍼 가방 열기)→충전→보조→배기→열 밀봉→성형 및 제품 출력. | ||

(귀하의 필요에 따라 독점적인 포장 기계 맞춤형 서비스를 제공할 수 있습니다! 물론, 필요하다면 맞춤형 가방 서비스도 제공할 수 있습니다)

![]()

![]()

![]()